With an eight-year development cycle including our optical, mechanical, and physics experts, the fourth iteration of the process head is without a doubt our greatest competitive edge over competing cleaning lasers.

Together with low weight and ergonomics, the final version of the helmet includes various precisely calibrated and distinctively designed features.

- A scanning system that is custom designed for smooth and uniform laser cleaning in multiple beam shapes. With adjustable beam shapes, our lasers not only increase efficiency, accuracy, and uniformity in cleaning but can also reach textured and grooved surfaces that basic laser cleaning cannot handle.

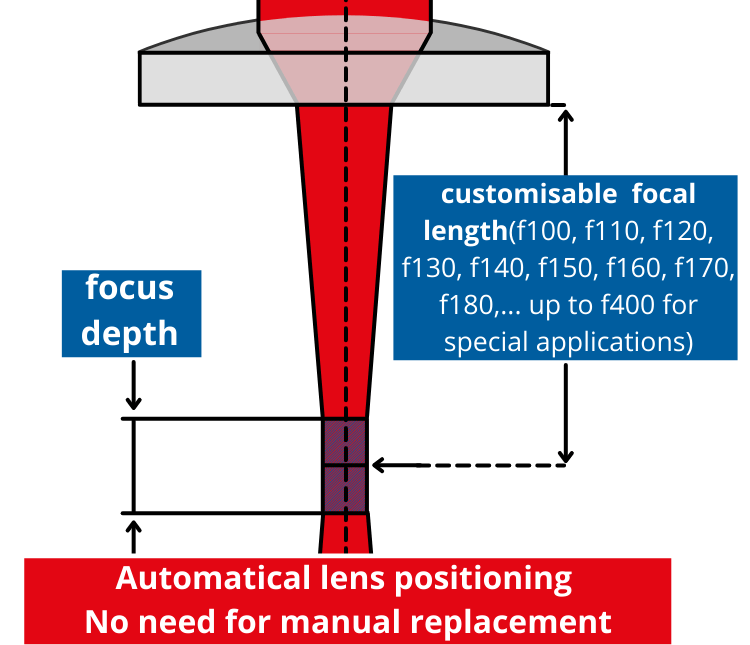

- The focal distance affects the areal density and also the distance of the process head from the cleaning point. Compared to competing systems, we offer an automatic change without physical intervention and therefore manual lens replacement. The focusing distance can also be adjusted in millimeters, so you can achieve results that were previously unthinkable. In order to be able to replicate the behavior of our optics on other systems, you would need tens of focusing lenses worth tens of thousands of euros. Laser optics are also very sensitive to dirt and any opening of the laser head during lens changes can lead to serious damage to the internal optics, mirrors, and process fiber, which can lead to unnecessary economic damage.

- Basic cleaning parameters (focus, scanning speed, scanning width) are adjustable directly on the process head, no need to go to the machine display (only for 500 and 1000W variants)

- Increased ergonomics and substantially improved comfort when working with the cleaning system for long periods of time. The ROD laser process heads are lightweight and have a non-slip surface treatment, and, above all, the optical cable can be put over the shoulder or manipulated in various ways for easier work if required.

- Active water circuit cooling (ROD 200 models and above) ensures trouble-free operation even in demanding conditions and three-shift operations.

- Can be attached to a manipulator, traverser, or robotic arm even retrospectively after the purchase of a laser. The industrial PLC is ready for communication with higher-level systems or external laser beam triggering.

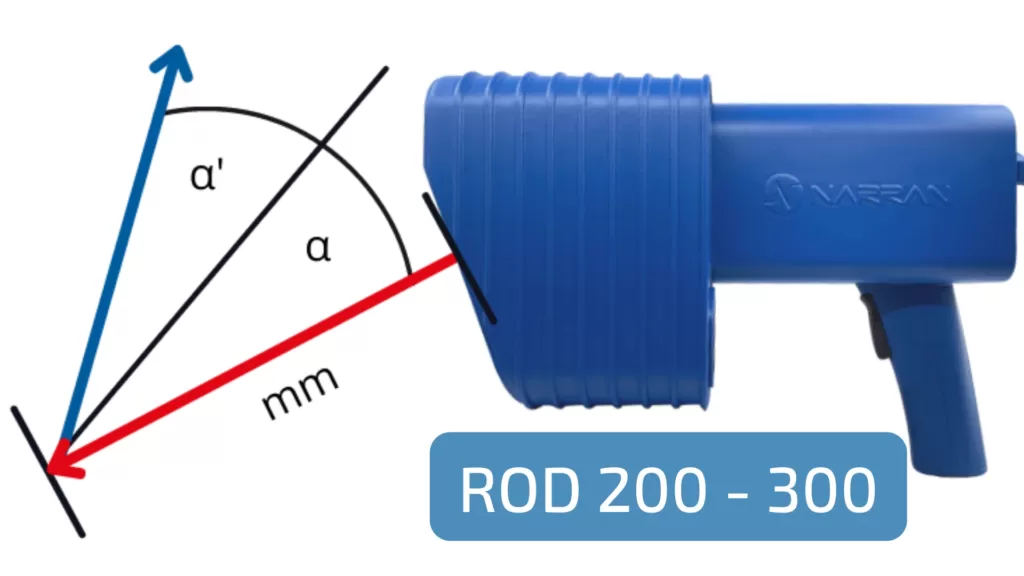

- By the angled output of the laser beam, the head eliminates back reflections of both the laser radiation and released impurities and fumes. The head is therefore minimally dirty and heated, so it requires less maintenance and this has a positive effect on its overall lifetime.

- The hermetically sealed lens of the optic ensures that it is virtually impossible to damage through normal operation, so you won’t have to deal with replacements that could otherwise cost hundreds of euros.