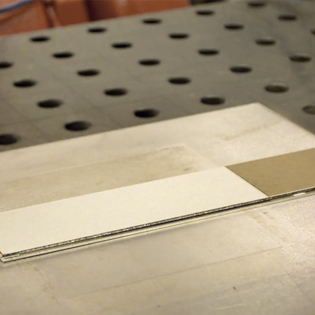

Narran Laser Cleaning machines can provide quick cleaning and surface preparation in virtually all industries. The low-maintenance, easy process to remove rust, corrosion, stains, strip paint or coatings. Allow surface texturing if required, for example, adding roughness to increase adhesion.

Narran Australia Laser Cleaning machines can provide quick cleaning and surface preparation in virtually all industries. The low-maintenance, easy process to remove rust, corrosion, stains, strip paint or coatings. Allow surface texture if required, for example, to increase paint adhesion.

- No abrasives were used, so no problems with contaminant separation or disposal.

- No solvents are used, making it chemical-free and environmentally friendly.

- Spatially selective – cleaning only required areas, saving time and costs

- The non-contact process never degrades the quality of base substrate materials.

- Automated processes can lower operating costs by reducing labour.